Accelerating MedTech Commercialisation

Discovery to Device will bridge the divide between ideas and products

Transforming ideas into products, to create real world impact

Discovery to Device transforms ideas into products, through prototyping and scale-up manufacture, to create real world impact.

We accelerate medical technologies commercialisation through specialised infrastructure, advanced expertise, accredited processes, and small volume manufacture.

Capabilities

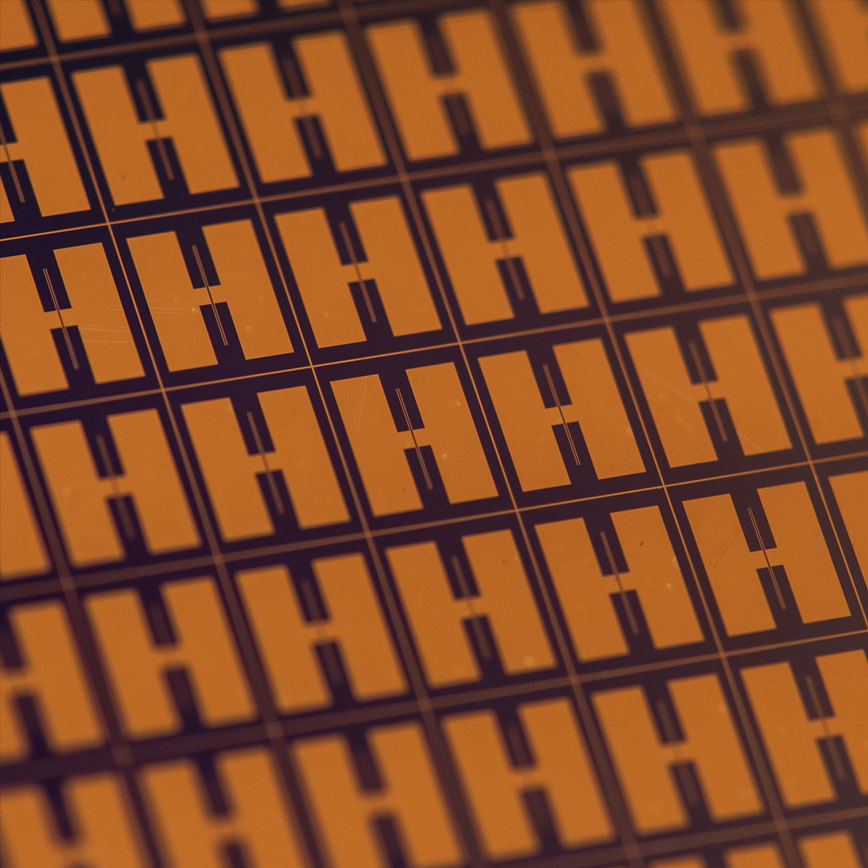

Patterning and

deposition

A Class 1000 (ISO 6) cleanroom environment for fabrication of biosensors, nanoscale patterning, and deposition of thin film coatings for functionalisation and electronic interfacing.

Machining and

assembly

Specialised equipment to undertake micro-machining at scales that allow skin-mounted wearables, specialised biocompatible materials for packaging of devices, and rapid production of design-influenced product enclosures.

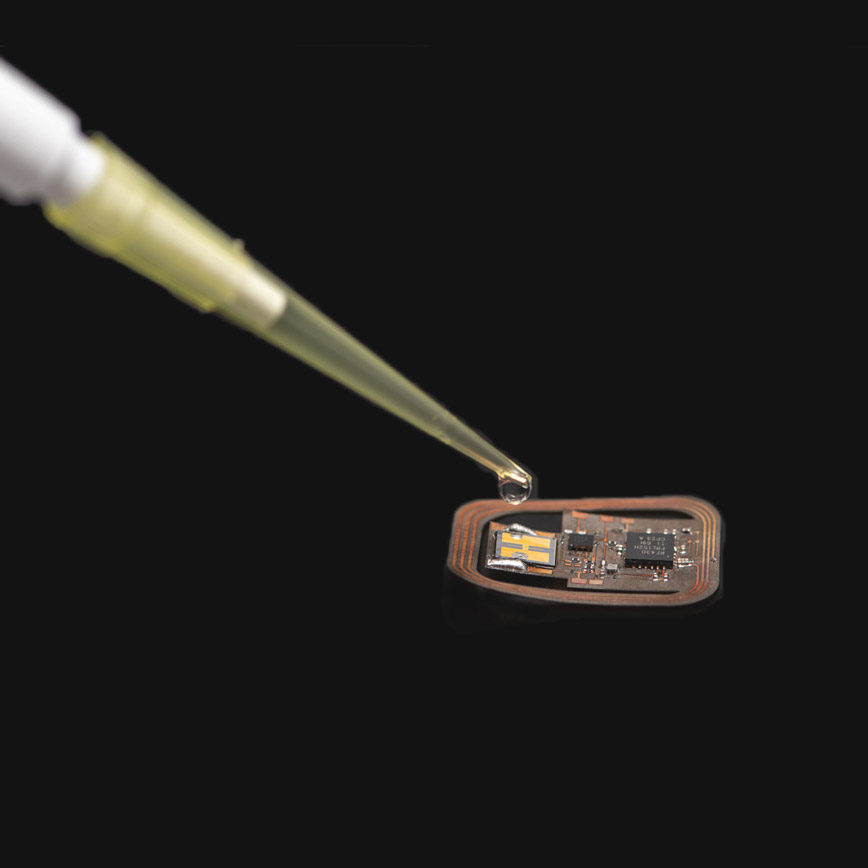

Biosensor

development

State-of-the-art capabilities to characterise biosensors including biological materials handling facility for surface functionalisation, treatment with target molecules, surface characterisation, and quantification biosensor performance characterisation and quality control.

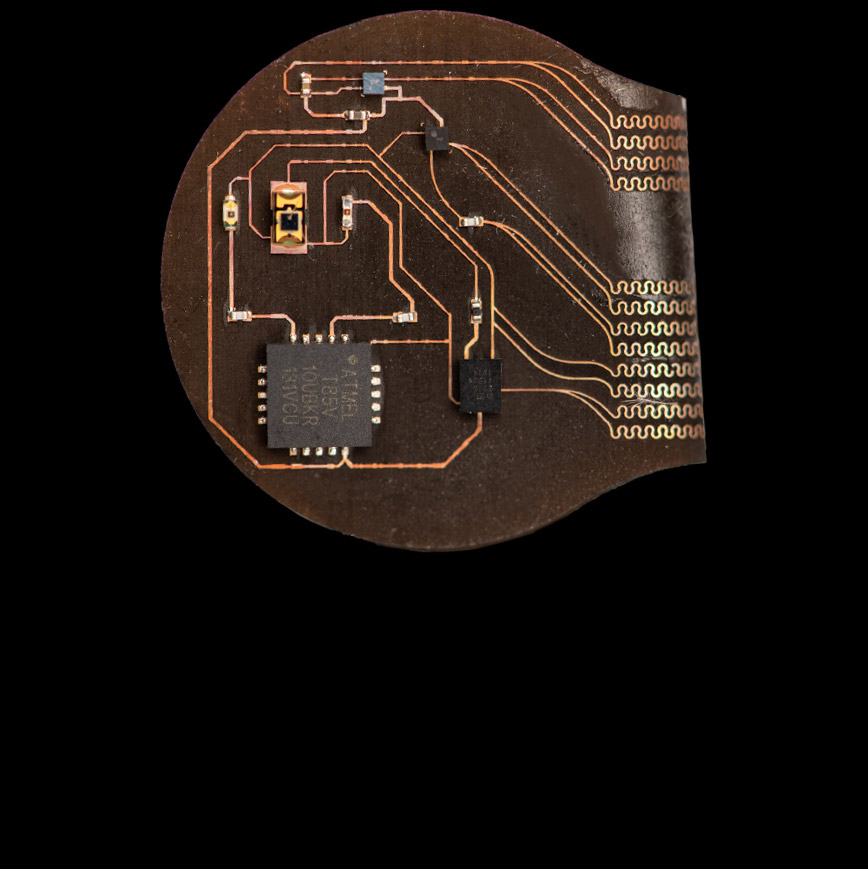

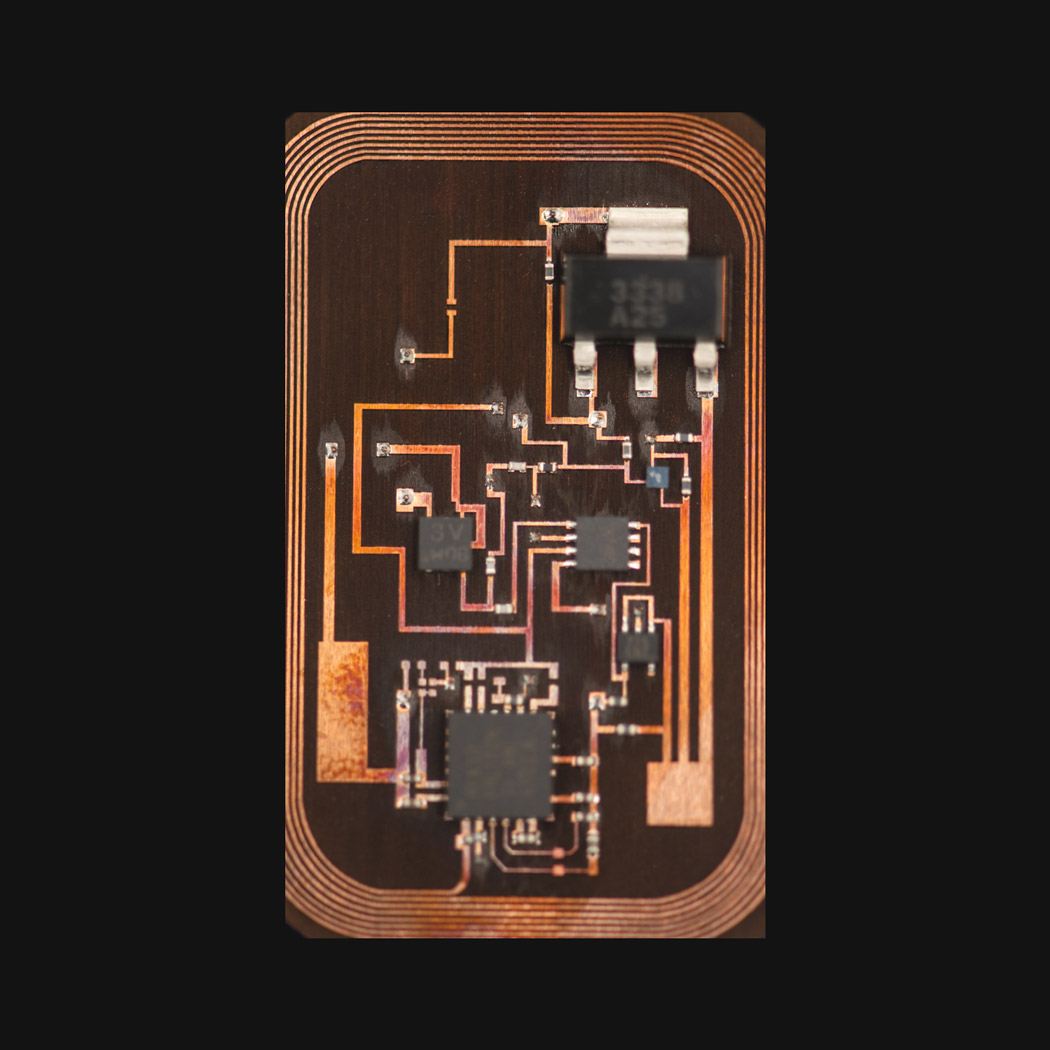

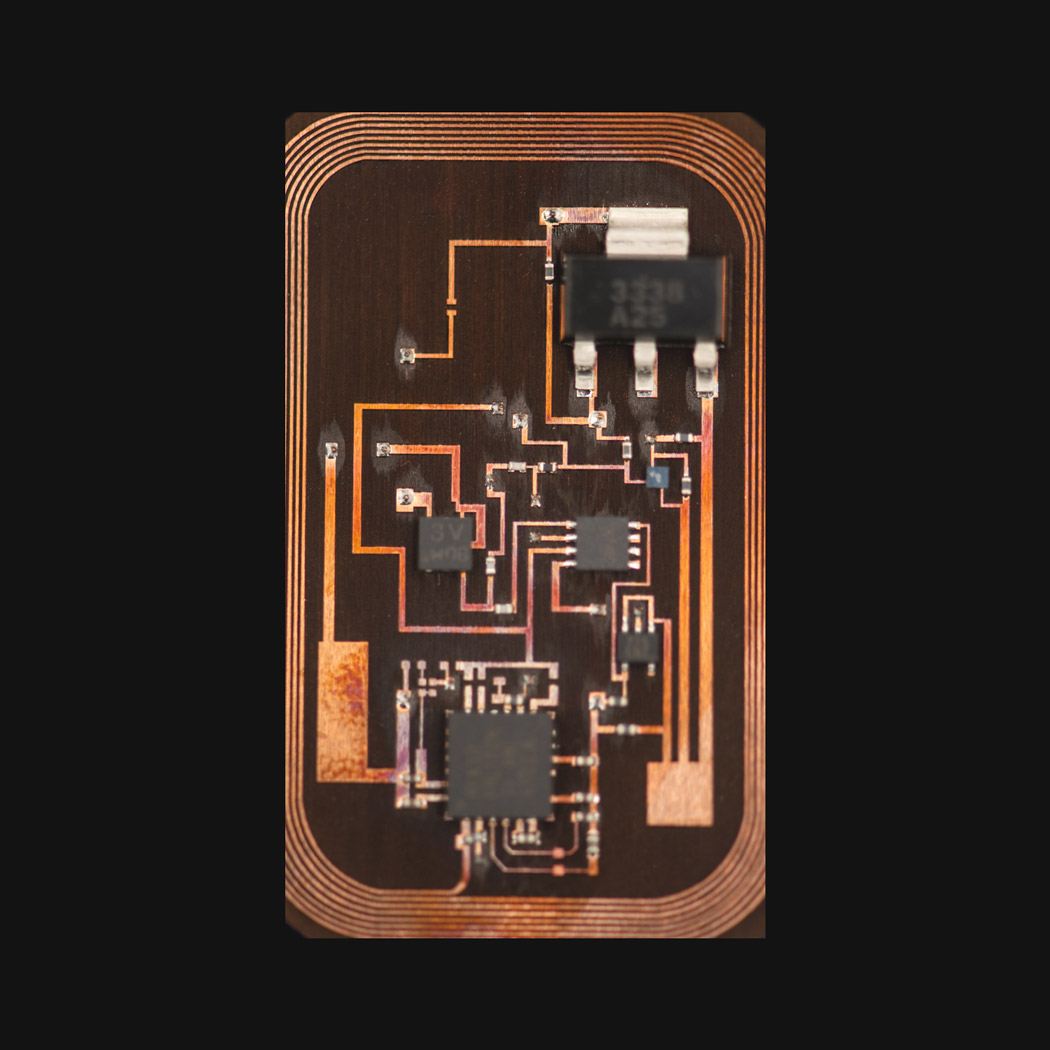

Electronics

integration

A Class 10000 (ISO 7) semiconductor cleanroom environment operating under ISO 13485 protocols, which allows rapid throughput production of ultra-light flexible electronics circuits and advanced laser-based electronics prototyping.

Sharath Sriram

Facility Director

Professor Sharath Sriram is a researcher and inventor driving an agenda of creating personalised and accessible medical technologies in a partnered ecosystem. He leads the establishment of this Facility to accelerate commercialisation of Australian innovations, enable sovereign low-volume manufacturing, and enhance skills development.